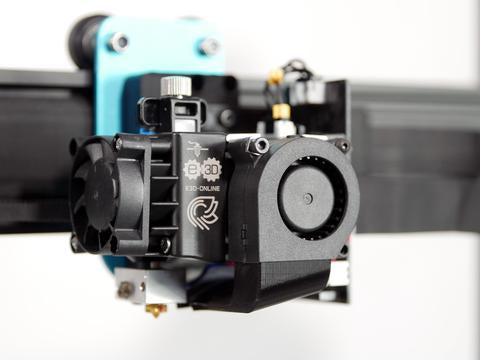

There is also a aluminium head assembly on AliExpress, but be careful, you may have to modify (drill/mill) to get it working. This appears to be a go-to hotend for high flow. Also it's quite heavy and the included linear bearings are trash. Simply put, the E3D Hemera, is a state-of-the-art dual drive extrusion system which has put performance and user-friendliness at the forefront of its. Not a huge fan, since it needs a specialized nozzle. A crossbreed of V6 and Mosquito, it takes V6 nozzles while pumping up a Volcano flow, at least on paper. Reports suggest that when it clogs, it clogs for good. And it is precisely because of the large drive gears 18mm 56.52mm perimeter our new LGX will have advantage on the grip. In retrospect I would recommend to start with a 3D-printed one. LGX Drive Wheel Not saying the Orbiter isn’t a good extruder. It is, especially when using our original QR 12mm 37.68mm perimeter drive gears. But there is a 50 increase in drive gear perimeter. Prints like a charm now (even flexibles). Nowadays there is a newer and lighter extruder in the market, the H2 from Biqu, just got one. The main difference between the Matrix and the Hemera is the use of a bi-metal heat break instead of the regular titanium heat break used on the Hemera. Gian) NCS ReleaseAbstrakt - U NCS ReleaseSTAR SEED- Cayenne (feat. Smaller motor (weaker torch), but relation 7:1 and total extruder weight of 119 grams (photo bellow). This makes the thermal performance a bit better while also requiring less airflow.

I previously reviewed the Trianglelabs Matrix and it performed really well. Zoe Moon) NCS ReleaseTollef - Take Our Time NCS Rele. I also get an allmetal/ bimetal heatbreak to avoid the one with internal PTFE tube (it cames with Capricorn in a bore 4.1 heatbreak I guess). It’s a good option for me convert to 1.75mm filament because it’s almost impossible to find 2.85mm here and when I found it’s triple the price and has a lot of moisture due to low demand 😓 Direct Drive Bondtech LGX Lite with Mosquito Magnum Hotend on Ender 7 with. The speed will be lower because of the extra weight but I always print slower than 60 and with bigger nozzles… and I’m printing a lot with TPU nowadays shores of 85A, 95A and 98A (semi-flex) so this should be a good direction even to print TPE /softer and showned in some demos. Although E3D Hemera is designed to be used as a direct extruder, it can also be used as a Bowden extruder simply by adding a small adapter. I will need to deal with firmware changes but it will not a problem since the brand provide a good explanation of it, just thinking how I will set the end stops and attach the entire extruder to the rods (combine with others designs provided above or remix the E3d adapter to UM2) the challenge will be keep a good balance on it… I will lose a bit of area in some of the axis probably and need to add a fan duct on it.

Although Hemera has been developed from the ground up, it has been ensured that it maintains compatibility with the entire E3D ecosystem of.

0 kommentar(er)

0 kommentar(er)